360° label inspection on pharmaceutical bottles

Case History Xyntek

The customer was asked by a pharmaceutical company to develop an inline vision system to verify labels on small plastic bottles at a rate of 60 ppm. The inspection required performing OCR to read the reference code, control or lot number on the label for Track and Trace purposes. Moreover, they had to verify that the label was applied correctly on the bottle: specifically the “double-label” issue was checked, that is when two labels were incorrectly applied to the bottle.

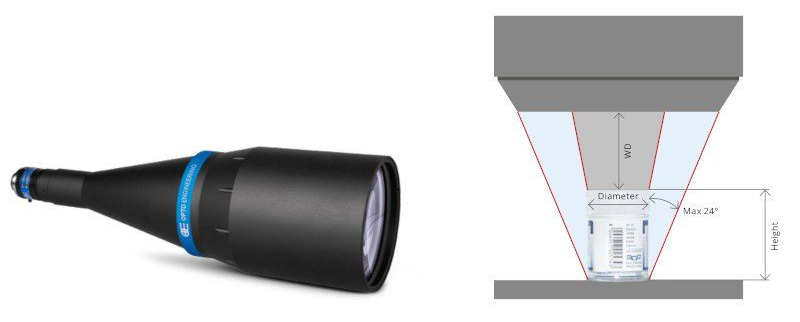

Choosing the right lens

Based on the size of the samples, a PC13030XS pericentric lens was selected. This model is part of the PC series by Opto Engineering®, a family of lenses designed to see the top and side of an object in perfect focus, all in one image. In particular, the PC13030XS is optimized for 1/3” sensors, with a field of view ranging from 7.5 to 55 mm in diameter and from 5 to 20 mm in height. Moreover, Opto Engineering® offers a line of dedicated lens mounts called CMHO series. In this case, choosing the CMHO080 clamp made it very easy to mount the lens into the system.

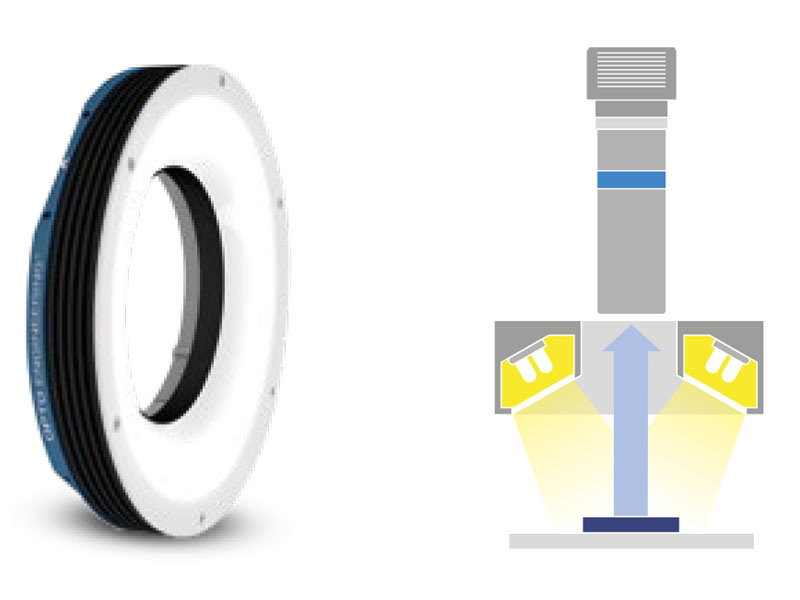

Choosing the right illuminator

Picking the right illuminator is paramount in every machine vision application but it can be a challenging task when specialty optics are deployed. To ease the process, Opto Engineering® offers a dedicated line of high-power LED ring lights specifically designed to offer the perfect illumination geometry for 360° view lenses. In this case a LTRNHP210W20 white ring light (see Figure 3) was selected to achieve very uniform illumination of the samples. By combining the ring light with a LTDV1CH-17V led strobe controller, the customer was also able to decrease exposure by 9 times.

Choosing the right camera

Once the appropriate optics and lighting were chosen, a suitable camera was also needed: in this case, a COE-050-M-POE-023- IR-C 5MP camera (see Figure 4) from Opto Engineering® COE-G series was selected. This series features GigE cameras equipped with the latest sensors, from high speed VGA to the latest 12MP SONY Pregius sensors. Their robust design is ideal for many industrial environments while the GenICam® compliant SDK allows for easy programming with most software packages.

Xyntek

Why Opto Engineering®?

Thanks to the unique patented design, PC series pericentric lenses by Opto Engineering® allow users to easily and efficiently solve machine vision applications such as the one presented in this case involving OCR on medical bottles. Thanks to our wide range of compatible products, we were able to provide a bundled solution to the customer including lens, camera, illuminator, strobe controller and dedicated clamping mechanics (see Figure 6). The successful development of the application was also aided by a quick and thorough feasibility study. Moreover, this project laid the foundation for a fruitful cooperation between Xyntek and Opto Engineering®. For instance, a similar application involving bigger samples was solved with a multi-camera system where COE cameras were once again the preferred choice.