Toothpaste cap inspection

Case History Shanghai Jiewei Automation Technology Co. Ltd

The test setup

In order to perform 360° inspection of the object with a single image using a 1/2” camera, a PCCD012 catadioptric pericentric lens by Opto Engineering® (Figure 2 ) was selected. Since this lens can only image objects with diameters up to 25 mm, a dedicated attachment called PCCDLFAT was added to the lens to extend the maximum visible diameter up to 35 mm. During the feasibility study, the image was unwrapped using the 360LIB Suite, a powerful software specifically designed by Opto Engineering® to maximize the performance of 360° view optics. As for illumination, the choice fell on the LTRN245W35 white oblique LED ring light from the Opto Engineering® LTRNOB series.

The results

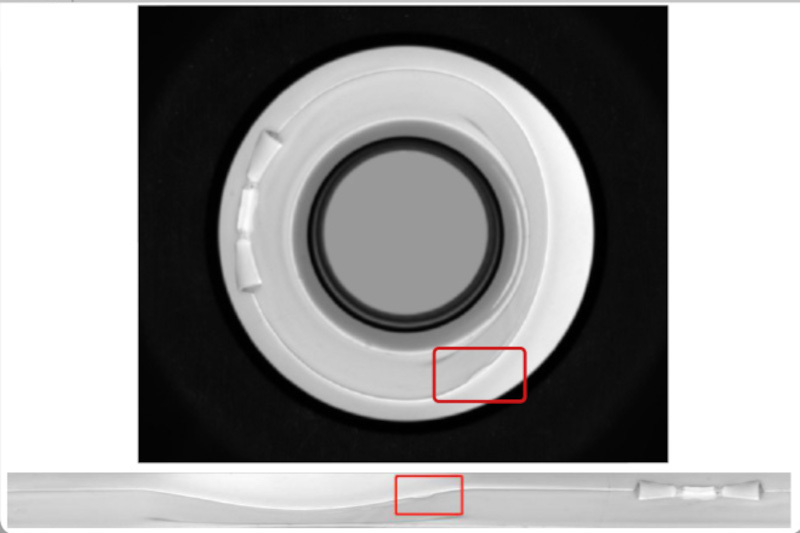

The PCCD pericentric lens is ideal to acquire a 360° view of the whole sample in a single camera shot. Production defects are perfectly visible both in the original image and in the unwrapped image (Figure 3). The very uniform illumination delivers good contrast across the whole field of view.

Why Opto Engineering®?

Thanks to the unique designs patented by Opto Engineering®, the exceptional build quality and the unmatched optical performance, 360° view lenses are the ideal choice for the all-round inspection of objects such as the toothpaste caps presented in this case. Avoiding multi- camera systems or movements of the sample/lens, these optics provide a simple yet extremely effective solution in many application fields. Moreover, Opto Engineering® has a worldwide Sales and Tech Support team that can help customers both in pre- and post-sale process, making sure that they get the best out of their vision systems.